When building products that include lenses, sensors, or imaging systems, the mechanical components responsible for holding and aligning these parts are just as crucial as the optical elements themselves. This is where opto-mechanical manufacturing comes into play—the precise machining and assembly of mechanical parts where accuracy directly impacts the optical system’s performance. This article explores what opto-mechanical manufacturing entails, why it is vital, and the industries where it is applied.

What is opto-mechanical manufacturing?

Opto-mechanical manufacturing involves producing mechanical elements used in optical assemblies, such as lens mounts, housings, brackets, and supports. These components not only secure optics but also establish alignment, stability, and repeatability. Even minor inaccuracies can cause significant issues in the final optical system.

This work demands:

- Extremely tight tolerances

- Clean assembly environments to prevent contamination or distortion

- A strong understanding of both optics and mechanics

If optical components are out of specification or misaligned, the optical system will fail to perform as intended, and these problems cannot be corrected later through software or operation.

The vital importance of alignment

and tolerance in opto-mechanical manufacturing

Precision is paramount in optical assemblies. Proper fit impacts:

- Image clarity and sharpness

- Measurement or inspection repeatability

- Stability of the light path

- Long-term system reliability

Misalignments cause distortions, parallax errors, or focusing problems. Thermal instability and mechanical flexing can disrupt critical alignments, degrading performance or causing system failure.

Applications of opto-mechanical manufacturing across industries

Opto-mechanical assemblies are essential in sectors where system reliability under real-world conditions is critical.

- Medical technology Imaging systems, diagnostic housings, and surgical camera assemblies require exceptional stability and cleanliness.

- Defence and aerospace Durable, vibration-resistant mounts support UAV optics, rugged sensor housings, and surveillance systems.

- Industrial metrology Non-contact measurement devices rely on exact mechanical alignment for accuracy and repeatability.

- Electronics and imaging Compact, precise optical setups are vital for digital microscopes and inspection cameras.

Qualities of a reliable opto-mechanical manufacturer

A high-quality manufacturer can:

- Maintain micron-level tolerances

- Assemble components in controlled environments

- Provide guidance on tolerance stack-ups and thermal effects

- Understand the interplay between mechanics and optics

- Deliver consistent quality in regulated settings

General subcontract machining lacks this specialised expertise.

Manufacturing processes in opto-mechanical production

These processes include advanced CNC machining, precision grinding, and polishing to fabricate components with tolerances often within a few microns.

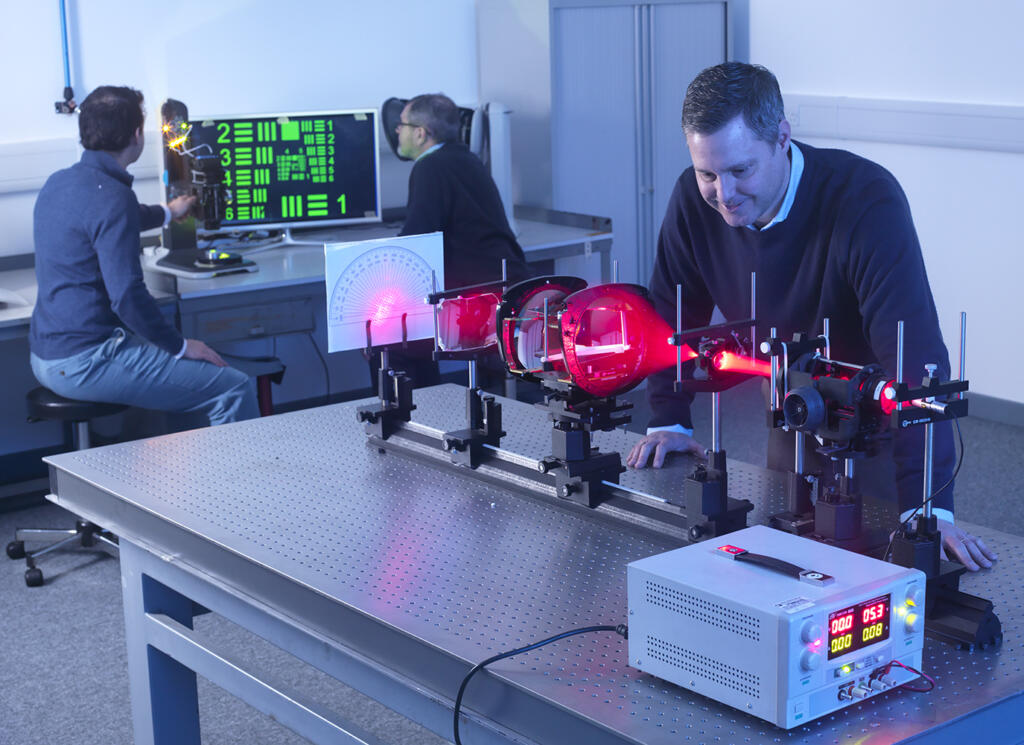

Assembly occurs in clean environments to prevent contamination. Specialised tools ensure components are mounted with accurate alignment along the optical axis. Handling mechanical elements integrated with optics requires care, often using vacuum pens and non-contact measurement devices.

For mass production, methods balance cost, efficiency, and quality, maintaining repeatability and reliability. Automation and quality control systems support consistent output meeting strict customer requirements.

Overall, opto-mechanical manufacturing combines precision engineering, material science, and clean assembly to deliver robust, high-performance optical systems.

Precision opto-mechanical manufacturing and optical components services

At Vision Engineering, we specialise in providing opto-mechanical manufacturing solutions that combine micron-level precision with robust mechanical design to enhance optical performance. Our expertise includes precision CNC machining, advanced assembly methods, and a deep understanding of the interplay between mechanical structures and optical components.

We produce assemblies such as lens mounts, brackets, and housings that ensure precise alignment and stability under varying environmental conditions. Our processes meet stringent tolerances required for high-performance optical systems, often achieving micron-scale accuracy.

Our cleanroom assembly and strict quality control minimise contamination and mechanical stress, preserving optical clarity and system reliability. By integrating mechanical expertise with optical knowledge, we deliver solutions that improve image quality, reduce optical aberrations, and ensure consistent performance throughout the product’s life cycle.

Complementing our mechanical manufacturing, Vision Optics offers a comprehensive range of high-quality optical components, including lenses, prisms, mirrors, filters, and coatings tailored to specific applications.

Our optical components services include:

- Custom design and fabrication of precision optics

- Advanced coatings for enhanced performance and durability

- Rigorous quality control and inspection to meet customer specifications

- Integration support for seamless assembly with mechanical structures

Providing both mechanical and optical components under one roof offers a streamlined, end-to-end solution that improves alignment accuracy, reduces lead times, and enhances overall system performance. This integrated approach makes Vision Engineering a trusted partner for complex optical systems.

Partnering with Vision Engineering Technology Partnerships gives you access to a full range of services—from design feedback and material selection to manufacturing and assembly—delivered with ISO 13485 and ISO 9001 certification. Our UK-based facilities support global clients across industries including medical technology, aerospace, industrial metrology, and electronics.

With a commitment to innovation and quality, Vision Engineering Technology Partnerships is your dependable partner for opto-mechanical manufacturing that meets the highest standards of precision, durability, and optical excellence.

Our opto-mechanical manufacturing expertise at Vision Engineering

At Vision Engineering, we take pride in designing, machining, and assembling our own optical systems — including flagship products such as the Mantis, the award-winning Lynx EVO, and the unique DRV-Z1 glasses-free digital stereo microscope. These products showcase the advanced opto-mechanical skills and expertise embedded in our manufacturing processes.

The DRV-Z1 is a state-of-the-art 3D digital inspection system requiring exceptional precision in opto-mechanical manufacturing to deliver accurate and comfortable stereo imagery in demanding industrial settings. Its complex lens mounts, housings, and optical assemblies are crafted to micron-level tolerances with meticulous alignment to ensure outstanding optical performance and durability.

The Lynx EVO stereo microscope, recipient of the Queen’s Award for Enterprise, combines sophisticated optical design with robust mechanical engineering, offering exceptional clarity, comfort, and reliability. Its success reflects our proficiency in manufacturing opto-mechanical assemblies that meet strict customer requirements and standards.

By developing these products in-house, we continually enhance our manufacturing capabilities, ensuring every component achieves the highest precision and quality. This close integration of design and manufacturing enables Vision Engineering to deliver solutions excelling in performance and reliability.

Our services for customers include:

- CNC machining of lens mounts, brackets, and housings

- Tolerances as tight as a few microns

- Clean, controlled assembly environments

- Design consultation on alignment and stability

- ISO 13485 and ISO 9001 certified manufacturing

- UK-based production with worldwide delivery

Manufacturing our own optical systems gives us deep insight into what makes assemblies function effectively and how to avoid potential issues.

Project highlight: Scaling up medical device manufacturing

We recently partnered with a medical device company to scale production of a critical diagnostic instrument. Leveraging our opto-mechanical expertise, we provided precision CNC machining and assembly of complex lens mounts and housings, meeting stringent tolerances and regulatory standards. Our cleanroom assembly and rigorous quality control ensured contamination-free production and reliable optical alignment.

This collaboration enabled the client to increase manufacturing capacity while maintaining high quality and compliance, demonstrating our ability to support demanding, high-volume medical applications.

Ensuring precision and excellence in opto-mechanical manufacturing

Opto-mechanical manufacturing is pivotal to the performance and reliability of modern optical systems. It requires understanding how mechanical factors influence optics and controlling these during production.

If your product depends on precise optical alignment and mechanical integrity, partnering with a manufacturer skilled in both is essential.

Explore our services and contact us to discuss your upcoming project, Get in touch.