Bringing a new product to market is exciting, but it can also be daunting. The manufacturing process must balance cost control with strict quality standards and on-time delivery. For many companies, trying to manage the entire production in house becomes both expensive and risky. That’s why so many businesses across different industries turn to a contract manufacturer.

What makes a reliable contract manufacturer?

Choosing the right contract manufacturer is not just about price. A dependable partner understands your industry and operates to recognised standards, ensuring every project is delivered on time.

With decades of engineering experience and ISO certification (ISO 9001 and ISO 13485 for medical device regulations), we give customers confidence that every production run is built to the same high level of quality. Visiting a manufacturer’s facility for a factory audit provides assurance through first-hand insight into working conditions and the quality of operations.

Why outsourcing manufacturing services works for companies today

Running a full manufacturing line is rarely simple. Machinery, staffing, raw materials and compliance systems all add significant cost. For a start-up companies, those costs can make production almost impossible. Even large companies often find that outsourcing helps them stay lean and allows their business development and sales teams to focus on growth rather than production problems.

Working with a contract manufacturer also spreads risk. Supply chain delays, equipment failures and compliance issues can all disrupt in-house operations, but outsourcing makes them easier to manage. It also creates flexibility. Companies can begin with early stage prototypes, test a minimum viable product with potential customers, and only scale once the product strategy is proven.

One concern many businesses raise is intellectual property. Handing designs and data to a third party is a big step, and the worry is understandable. We take this seriously. Our controls are designed to protect your information at every stage, so your property remains secure throughout the manufacturing process.

A good example comes from the UAV industry. A customer needed to move from small concept kits to a reliable final product for the UK Police. By stabilising their supply chain and setting up structured manufacturing operations, we delivered 50 units in the first year, each one built to a consistent quality standard.

The product development process: From idea generation to market delivery

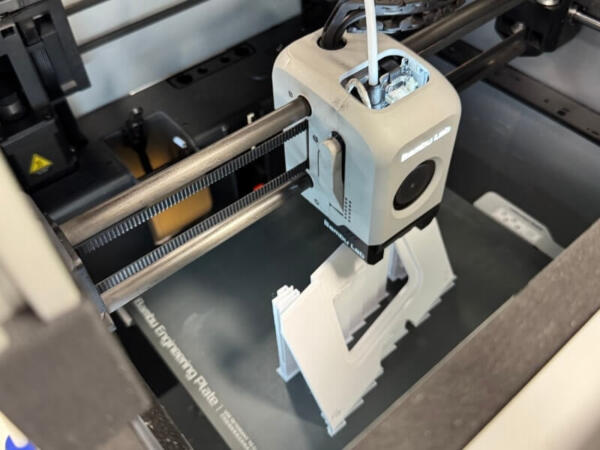

Every development process begins with an initial concept. From there, it moves through idea generation, early stage prototypes and validation. A strong product development plan with clear key metrics and a roadmap helps teams monitor progress. Creating a minimum viable product at this stage is invaluable. It generates real data on product performance, reduces development time and gives senior managers the confidence to keep investing.

Agile product development and the value of early stages

Agile product development has become a common approach because it shortens development time and keeps costs under control. Moving quickly from initial design to the prototyping phase allows companies to test products, gather customer feedback and fine tune the product strategy before committing to full production.

This kind of approach makes sense when markets move quickly. It also helps product managers and their teams gain a clearer understanding of what potential customers value most.

What design for manufacturing really means

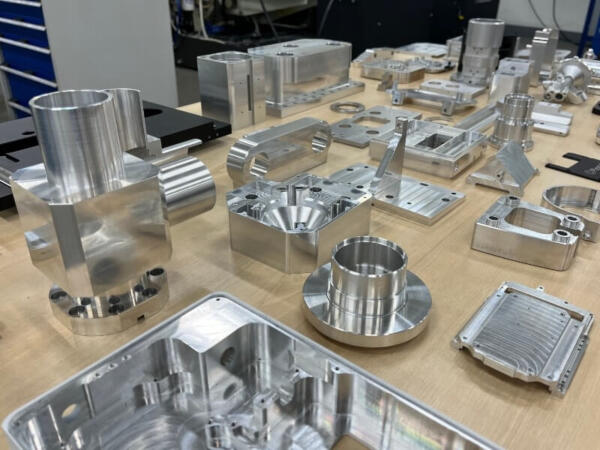

A design that looks right on screen can still be costly or slow to manufacture. Design for manufacturing ensures the design process considers material use, wall thickness, draft angles, surface finish and how components will fit together on the manufacturing line.

By simplifying assembly, companies can reduce cost, improve yield and cut down on errors. Streamlined processes save time and make the overall process more reliable for both the manufacturer and the customer.

In the medical industry, the BulbiCAM device shows the impact. By fine tuning the design, simplifying build steps and improving consistency, we created a finished product that met clinical requirements and scaled smoothly into production.

Scaling from prototype to production with confidence

The move from prototype to production is often where projects face the most risk. Costs rise, deadlines slip and quality can drift without a structured process. A contract manufacturer with proven methods manages this transition through pilot runs, documented operations and secure supply chains. Customers gain visibility at every stage, with confidence that the final product will perform as expected in the market.

That was the case in the UAV industry, where early prototypes were turned into production units that reached operational teams on time.

Partner with a proven contract manufacturer to take your product further

In every industry, contract manufacturing offers customers a way to bring products to market with lower risk and greater flexibility. A clear development process, supported by design for manufacturing and a structured path from prototype to production, makes it possible to reduce cost and deliver products that meet real market needs.

Start-ups can reach the market without heavy in-house investment. Established companies can increase capacity, improve efficiency and strengthen profitability. In both cases, the right contract manufacturer can turn an initial concept into a finished product that customers trust.

We are certified to ISO 9001:2015 and ISO 13485:2016, we build quality and compliance into every stage of manufacturing. With 68 years of expertise, we help take products from prototype to production with confidence.

If you are preparing to launch or looking to scale, now may be the right time to review your approach. Contact us to see how we can support your next step.