If you are researching medical device manufacturing, you want practical guidance as well as a reliable build. You also want an ISO 13485 certified partner who understands the medical device industry and can help you progress an idea, a prototype or an existing design into a traceable production route. Vision Engineering Technology Partnerships gives you this support in the UK with clear engineering input and a structured quality management system.

Many early medical device companies face similar pressures. Projects can be delayed by unstable supply chains or higher costs, especially when the regulatory route is unclear. You might have a working model but no clear manufacturing process. You might also be unsure how your device fits into current UK MDR expectations, the CE mark, UKCA marking or class-based key requirements. Our role is to give you a clean, predictable path forward that supports regulatory compliance and future market access.

How we support your product

We help you bring your device into a repeatable build that aligns with regulated industry practice. You receive manufacturability guidance along with sourcing help, and your device is built within an assembly process that follows our ISO 13485 certified Quality management system. This gives you full traceability with supplier oversight and clear documentation as your device develops. You also gain structured risk management throughout development.

The aim is simple. You understand your device. We help you build it reliably, reduce risks and prepare it for market without adding complexity.

Quality management system ISO 13485 : 2016

Quality sits at the centre of our work. Our ISO 9001 accreditation gives you strong process control, while our ISO 13485 certification supports the specific needs of medical devices. You get a structured system that manages suppliers, materials and every stage of assembly through clear documentation. This helps you build a device that stays consistent, safe and ready to scale. This approach aligns with relevant international standard expectations and supports a smooth certification process.

Our team uses modern manufacturing technology and practical engineering experience to deliver precise, reliable builds that match your specifications.

As medical devices become more connected, cybersecurity is increasingly important. We follow strong security practices and are progressing toward Cyber Essentials Plus certification, supporting safe handling of customer information and project data.

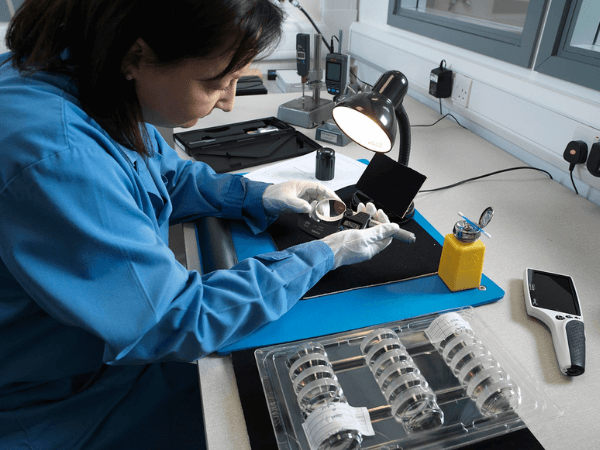

Cleanroom assembly

We support medical devices that need controlled conditions through cleanroom assembly and dust-free workspaces. Our facilities include temperature-controlled calibration areas and modern inspection equipment. This helps you maintain accuracy, stability and repeatability across each build stage.

Our team has deep experience building high-precision instruments that span optical, mechanical and electronic applications. We also support devices that rely on imaging or advanced monitoring. This sits alongside our wider contract manufacturing services, giving you a reliable route for high-precision devices inside our UK manufacturing facilities.

What you gain in the medical device industry

Working with a UK medical device manufacturer gives you practical advantages that make development easier and improve overall efficiency.

You gain:

- a clear route from sample to production

- guidance on materials, tolerances and assembly choices

- support with sourcing when supply chains shift

- a documented process that shows how your device is built

- consistent quality under ISO 13485

- shorter feedback loops because the build is local

- help understanding classification, marking and CE marking

- structured processes that reduce costly mistakes

These points matter for medical devices because the build process is as important as the design itself. A reliable production route helps you manage risk while keeping costs under control, and it positions your device for clinical use.

What you need when planning a medical device

You do not need a full technical package to start. A prototype, model or early drawing is enough to open a conversation. We help you identify what can be built as it is and what needs adjustment. Many medical devices benefit from early sourcing work, small design refinements or clearer documentation before moving to production.

These steps help you reduce risk, control cost and avoid rework later in the product lifecycle.

Moving from idea to production

Medical device manufacturing spans early development through to testing and scale-up, with post-market monitoring later in the lifecycle. We help you move through those early phases with a clear path, structured processes and practical engineering support.

If you have an idea, prototype or existing device and want to build or scale it in the UK, share your files or early models. We will review the most practical route from where you are now to a production-ready medical device.